Space Only Double Decker Stands

This information must be read in conjunction with:

Space Only/Double Decker exhibitors can appoint a stand Contractor of your choice to create a stand to fit your brand image and budget. Please ensure that you and your contractor(s) fully understand and adhere to the below build rules and regulations. These regulations are in place to create a safe and conducive environment for all, ensuring that Space Only stands are built as non-blocky structures and do not obstruct the visibility of neighbouring stands. IBC welcomes creativity and innovation, and all stand designs will be reviewed with this in mind whilst ensuring rules are enforced as fairly as possible with an unbiased view. IBC reserve the right to refuse designs, or request amendments to designs, which in their opinion may have a detrimental effect to neighbouring exhibitors or the overall look of the exhibition. If you are building a Double Decker stand, please ensure that you have informed your IBC Account Manager, as a charge for the 2nd level is applicable. Double Decker stands are not permitted in Hall 14.

|

|

STAND PLAN SUBMISSION - IMPORTANT INFORMATION

STAND PLAN SUBMISSION IS APPLICABLE TO THE FOLLOWING EXHIBITORS:

- All Space Only Stands including Double Decker Stands

- All Outdoor Exhibits including any vehicles displays without any build

- All Balcony Suites built by any 3rd party contractor other than the event official supplier - RAI Exhibitor Services

- All internal fitouts of pre-built Package 2 Meeting Suites and pre-built Balcony Suites by any 3rd party contractor other than the event official supplier - RAI Exhibitor Services

- Internal fitouts of any RAI Meeting Rooms by any 3rd party contractor other than the event official supplier - RAI Exhibitor Services

- Shell Scheme Stands planning physical construction within their stand (only if using your own third-party contractor, other than the event official supplier - RAI Exhibitor Services)

- Any stand exhibiting a ‘Restricted Goods’ – see Health & Safety rules

All Space Only exhibitors must submit fully detailed and scaled technical plans for approval on structural soundness and compliance with the rules and regulations set out in the IBC Exhibition Manual, venue and EU health and safety regulations including the use of venue and EU permitted stand build materials and electrics. Exhibitors are reminded that it is their responsibility to ensure the stand design and build conforms to these regulations.

Abraxys Ltd, IBC's appointed stand plan inspection agency, will be reviewing all stand design plans and supporting Health & Safety documentation. IBC has the final discretion over all builds and may therefore enforce alterations to any unapproved designs. Abraxys will be supervising the onsite build ensuring that stands are being built according to the submitted plans. Stands where plans do not meet the rules will not be permitted to be built. IBC, the RAI Amsterdam, RAI Structural Engineers and Abraxys/Campbell Reith, reserve the right to request structural calculations, approved pre-show or onsite, for any stand structure at the event should they deem necessary. All costs relative to obtaining proper certification are liable to be paid by the exhibitor.

Double Decker stands are subject to a TWO-STAGE approval process involving two separate bodies, Abraxys and the RAI Licences Desk. It is only upon complete approval of BOTH parties that a design is deemed as fully and finally approved. A design approved by Abraxys in the first stage of the approval process may be subject to further design changes and modifications on the grounds of health and safety as/if requested by the RAI Structural Engineer.

STAGE 1: Submission of relevant stand plan and build documentation to Abraxys

General approval of a design concept by Abraxys based on IBC’s show rules and regulations as to what is deemed acceptable for the IBC show environment. The Double Decker stand plan submission process also includes confirming the 2nd structure being built and the Double Decker working at heights confirmation to show the planned control measures to prevent accidents when working at heights. Working at heights without adequate preventative measures in place is strictly not permitted and will be stopped if necessary.

STAGE 2: Submission of relevant stand plan and build documentation to the RAI Licences Desk

In depth structural and health and safety approval based on structural loading calculations and health and safety elements (number of staircases, number and location of emergency exits, handrail and step tread design etc.). Whilst Abraxys may give general advice on these elements, each Double Decker stand is judged on an individual basis by the RAI Licences Desk whose decision is final. Designers are strongly advised to seek early advice on these elements as to what may be permissible within their stand design.

WHAT PLANS MUST BE SUBMITTED AND TO WHOM: One set of plans and the applicable Health & Safety documents must be submitted to Abraxys via the Stand Plan Submission link, and must include as a minimum:

1. Detailed technical plans in a recognised scale not less than 1:50 detailing:

- Event name (IBC2024), Stand number & Exhibitor name

- 3D graphic of the stand design

- Plan view clearly showing all dimensions, walling and major exhibits

- Plan view(s) showing the orientation in the hall and how transparency and sightlines will be achieved

- Scaled side and height elevations showing a clear indication of the height of various elements including graphics

- Vision panels in all storage and/or meeting room doors

- Platforms – height, materials and details of wheelchair access ramp dimensions

- Any rigged structures including dimensions and height of the rig

- Any hanging banners including their dimensions and hanging height from the floor

2. Onsite contact person and mobile phone number

3. Detailed information about the materials being used including up to date fire resistance certificates (see Permissible Stand Building Materials)

4. Risk Assessment and Method Statement for the installation and dismantling of the stand

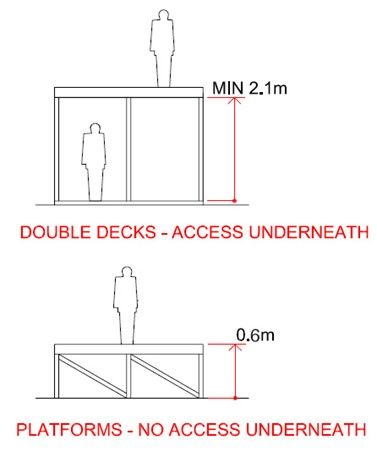

ADDITIONAL REQUIREMENTS FOR DOUBLE DECKER STANDS (including any stand with a 600mm or higher viewing platform or stage)

If you are building a Double Decker (incl. any stand with a viewing platform or stage 600mm or higher), you are required by law to submit a second set of plans to the RAI Licenses Desk, the official double decker structural engineers for the event, to obtain a Double Decker Build Permit. Once approved by Abraxys, fully detailed and scaled plans with points 1-4 above and including the below additional information must be submitted to RAI Licenses Desk.

5. Distribution plans of both levels of the construction (if not included with the above documents)

6. Calculations of the main structure which must include the following:

- Full structural calculations of all build elements, taking into account the maximum floor loadings of the exhibition floors.

- Details about the load transmission of pillars to the exhibition floor of any upper surface.

- Details about the maximum horizontal impact strength of any walling or handrail element (should be minimum 1kN per m).

- Author of the calculations, title, date of drawing & full contact details.

RAI Health & Safety Officer has the final say on what is permissible in terms of stand build on the day. Should there be any concerns regarding the safety of any element of stand construction, compliance with any changes imposed is mandatory. IBC will not be held responsible for any costs that may be incurred as a result.

Double Decker Surcharge: Exhibitors who have booked space for a Double Decker stand will be charged a surcharge for the upper deck. The calculation of the surcharge is based on the total square meterage taken up by the physical construction elements forming the upper deck such as stairs, balustrades, walling or any other element of physical construction on the upper deck. The definitive size of the upper deck will be determined by the RAI Licencing Officer. The charge is based on 25% of the floor space rate at time of booking.

HOW AND WHEN TO SUBMIT YOUR PLANS: Early submission of stand designs is strongly advised as it enables Abraxys to work with you, advise on and resolve any potential issues that may arise pertaining to your stand design. Abraxys request the final version of your stand design, please refrain from sending interim stand designs if you are aware that it will change imminently. Should you require making modifications to your stand design after the approval, you will be required to re-submit your design which may cause delays.

Fully detailed, scaled technical plans must be submitted to Abraxys by 20 June to avoid any increased inspection fees. If you are building multiple stands, you will need to submit the plans and pay fees separately for each stand.

Double Decker documentation, including structural calculations, must be sent for structural inspection to the RAI Licenses Desk via the Double Decker Build Permit Application in the RAI Webshop. It is a legal requirement for any Double Decker stand to be approved by the RAI Licenses Desk before full approval is granted:

- Please submit the final version of your stand design. Photographs or drawings will not be accepted.

- Plans and associated documentation must be in English and must be submitted in either .pdf or .dwg format.

- All Space Only Exhibitors must have a copy of their approved stand design, Method Statement and Risk Assessment on site.

Once you have been granted a ‘Permission to Build’ certificate by Abraxys (and the written approval from the RAI Licences Desk for additional Double Decker inspection), no alterations can be made to the stand plans submitted.

Permit applications should take into account the relevant Dutch Building Standards for Double Decker stands such as strength, stability and point loads including railings and stairs. It is highly recommended that exhibitors and/or their contractors contact the RAI Licences Desk for any further details before designing their double decker stand. IBC will not be held responsible for any costs incurred by the exhibitor as a result of requested design changes on the grounds of health and safety by the RAI at the second stage of the approval and permit application process (e.g. number of staircases, types of stairs, number of emergency exits etc.). A Double Decker stand design approved by Abraxys may be subject to further design changes should it be deemed necessary by the RAI Licenses Desk. A Double Decker Build Permit fee will be charged by RAI Licenses Desk. If a Doubled Decker stand is built without a permit, the authorities have the right to close off the stand or prevent it from being built. The local authorities are now very strict, and no exceptions will be made. Deadline to apply for the Double Decker Build Permit will be published in due course.

STAND PLAN INSPECTION FEES: Stand plan approval is subject to the Stand Plan Inspection (SPI) fee which is part of your overall stand plan submission. The SPI fee of GBP 175 (+ 20% VAT) will be charged by Abraxys upon receipt of your stand plan submission (all Space Only stand designs, including straight repeat designs from previous years, will incur an inspection fee). For late stand plan submissions after 20 June, the SPI fee will increase to GBP 300 (+20% VAT). A ‘Permission to Build’ certificate will be emailed to you (or your contractor) once the plan submission process is complete. Payment of the SPI fee can be made via the secure Abraxys retail site.

- SPI Fee (GBP): https://www.abraxys.online/online-store/IBC-2024-Stand-Plan-Inspection-Fee-p530099457

- SPI Fee (Euro): https://www.abraxyseuro.online/online-store/IBC-2024-Stand-Plan-Inspection-Fee-p530120035

Abraxys Ltd

Tel: +44 (0) 20 8747 2045

Email: ibc@abraxys.com - No stand plans/forms to be submitted via email. All submission to be made via Stand Plan Submission link.

A Double Decker Build Permit fee will be charged by the RAI Licences Desk. Should the RAI Licences Desk request any modification to your design, any additional costs incurred as a result will be the sole responsibility of the exhibitor.

RAI Licences Desk

Tel: +31 (0) 06 2250 8611

Email: permits@rai.nl

AERIAL DRONES

Static arial drones are permitted at IBC for display purposes to showcase the functionality of the product. You can display static drones on your stand without prior permission, providing these are not flown. IBC reserve the right to monitor aerial drone displays and presentations. If you want to fly a drone on your stand, you will need to take special preparations to prevent accidents. You must build a cage to contain the drone(s) when in flight and include the cage details in your stand plan or submit details to Abraxys if you are a shell scheme stand. You must obtain an official Drone Use Permit from the RAI by 15 August to fly your drone(s) within this cage and you will need to include information about the safety measures you will take when flying your drone(s). Drones flown without the RAI permit will be confiscated for the duration of the event.

- Aerial drone(s) must stay contained within the boundaries of your stand. Drones are not permitted to enter other exhibitors’ stands or the aisles of the show floor.

- Details of the aerial drone(s) must be included in your Risk Assessment and Method Statement and supplied as part of your stand plan submission or separately if you are a shell scheme exhibitor.

- It is never allowed to fly a drone(s) outside the RAI due to the Schiphol Airport flight path.

AIR-CONDITIONING

Exhibition halls are climate controlled during the exhibition and exhibitors are therefore not permitted to install their own air-conditioning systems. Professionally installed air-conditioning systems can be ordered upon request via the RAI Exhibitor Services. Air-conditioning systems create unnecessary heat preventing optimum use of the RAI cooling system. Exhibitors found to be installing and using own air-conditioning units, will be requested to turn these off, even if these are the correct units. All units must be ordered via the RAI Exhibitor Services. Please ensure the positioning of the air-conditioning units is included in your stand design. The deadline to order air-conditioning units is 21 August.

The inclusion of false ceilings on exhibition stands may prevent air cooling from working effectively. False ceilings on stands can create "hot-spots", in particular where lighting, monitors etc. are installed, and therefore should be avoided. To avoid generating unnecessary heat, use of "cold lighting" on stands is encouraged.

ANTENNAS & SATELLITE DISHES

ANTENNAS AND SATELLITE DISHES - RENTAL: A temporary satellite dish location and installation can be requested via the Hire and Installation of Satellite and Feeds Form which must be submitted by 24 July. IBC’s Verified Supplier Prospectrum will select the location for your satellite dish depending on the distance between your stand and the line of sight required. Most sites are located on hall roofs. Costs for hoisting and cable connections to your stand will be invoiced directly to the exhibitor. Prospectrum services include:

- Hire and installation of (dish) antennas for the reception of Satellite and Terrestrial Broadcast.

- Turnkey solutions including cabling of "Live Feeds" in DVBS, DVBT and DVBC standards.

- Feeds from Astra 19.2 East and Hotbird 13.0 East.

- The provision of all FTA DVBS, DVBS2 and DVBT channels.

- Package Deals incl. roof space, inter-stand cabling and antenna rentals.

- SATTV-Cabling, routing and switching at your stand.

- Specialists on site to support you.

Prospectrum Satellite Services

Jan op den Brouw

Tel: +31 (0) 653 132 745

Email: ibc@prospectrum.nl

ANTENNAS AND SATELLITE DISHES - CABLING: Cable requirements for Antennas and Satellite Dishes can be ordered via the Cable Requirements for Antennas and Satellite Dishes Form which must be submitted by 24 July (orders after this date will incur a 25% surcharge). Mansveld Expotech is the sole official contractor for cabling between stands and satellite dishes or antennas (e.g. data, coaxial or fiber). Based on requirements, Mansveld Expotech will quote for the work involved.

Mansveld Expotech

Fred van der Kroon

Tel: +31 (0) 20 312 8080

Email: sales@mx.nl

BALLOONS & HELIUM - UPDATED 01/07/2024

If you are intending on having balloons or helium filled products on your stand, please ensure the visual, measurements and positioning of these is included on your stand design plan. You must order these direct from the RAI Webshop - es@rai.nl and no balloons or helium canister can be brought in or used in the halls unless supplied by the RAI:

- Exhibitors are not permitted to bring helium canisters into the RAI.

- Filling of helium products is only permitted by the RAI. Exhibitors are not permitted to bring helium canisters into the RAI.

- If air or helium filled products used as part of a stand design or display escape their tethering, exhibitors will be responsible for retrieval charges and any related charges.

- Suspended banner and promotional balloons are only permitted in accordance with the IBC Skyline Zone rule - see Skyline Zone section below.

- Due to the danger to Schiphol Airport air traffic, hand-held balloons are strictly prohibited anywhere in the RAI.

- Helium balloons must not be emptied in the building. This must be done outside in liaison with the Event Manager.

BUILDING HEIGHT

The following strict height limits apply at IBC:

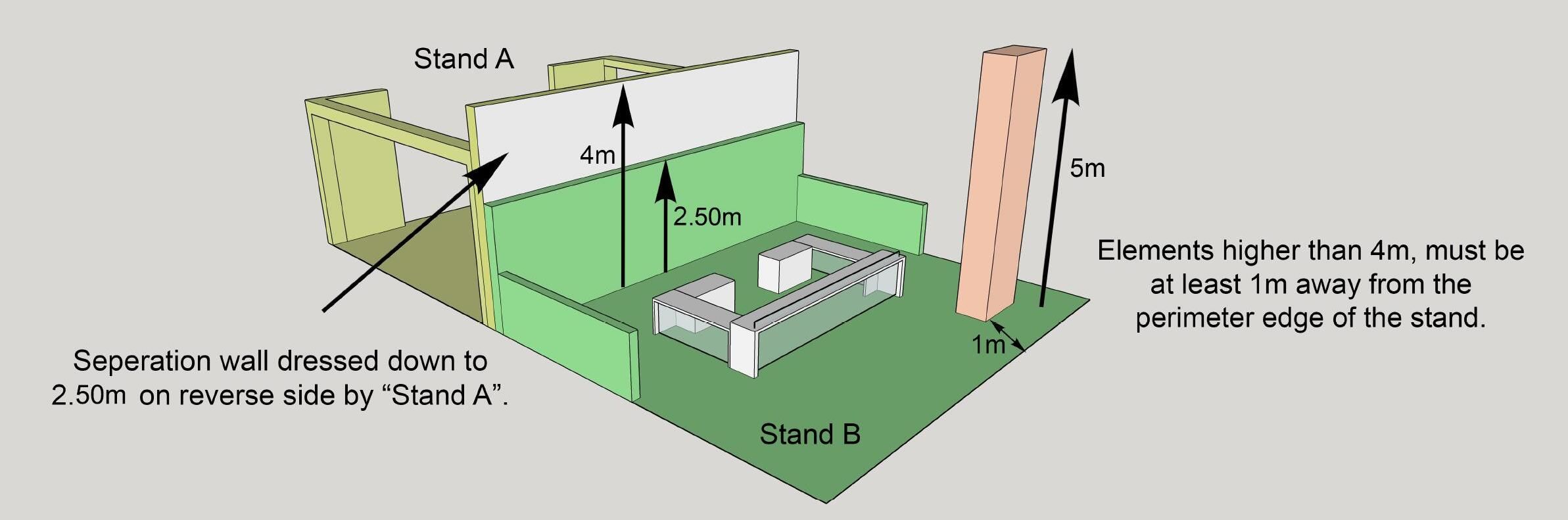

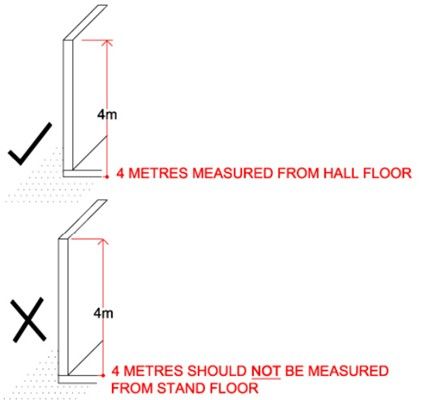

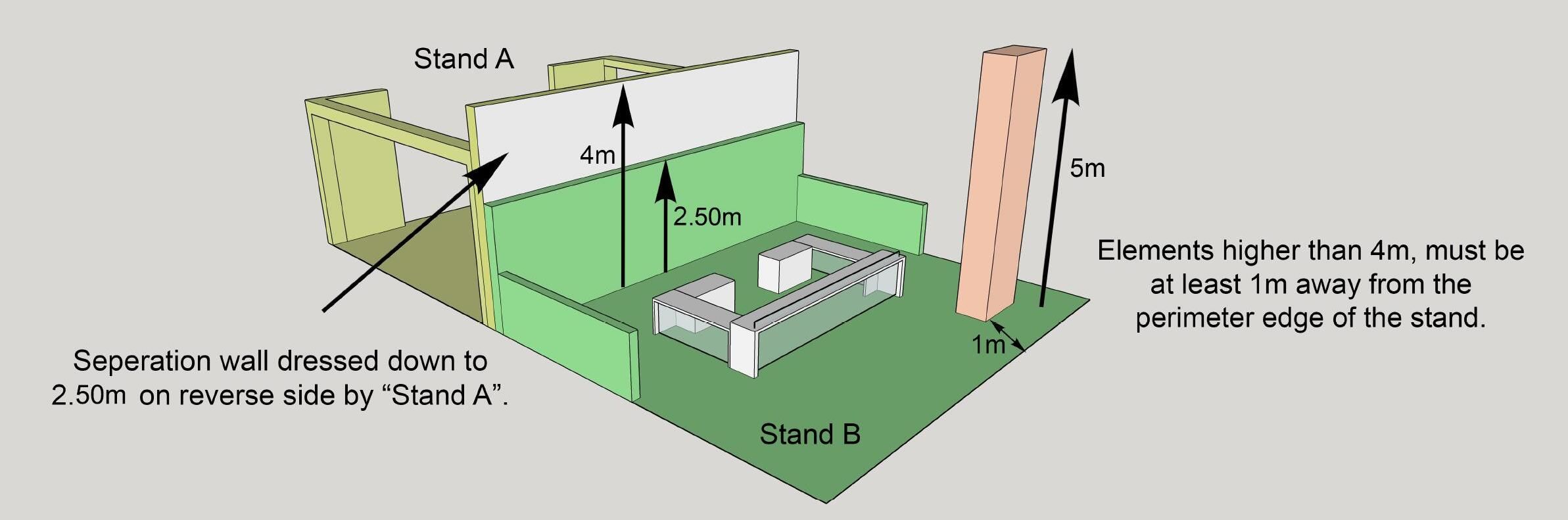

- Separation walls - minimum 2.5m and maximum 4m (inclusive of any platforms and flooring)

- Separation walls for adjoining Double Deckers only - maximum 5m

- Perimeter/outer edge walls and column structures (i.e. 6m or less in length) on the stand edge - maximum 4m

- Logos, structures and/or banners above 4m - set back at least 1m from the separation wall(s) and at least 1m from any perimeter wall(s) and outer edge(s)

- Logos are not permitted on the reverse of separation walls

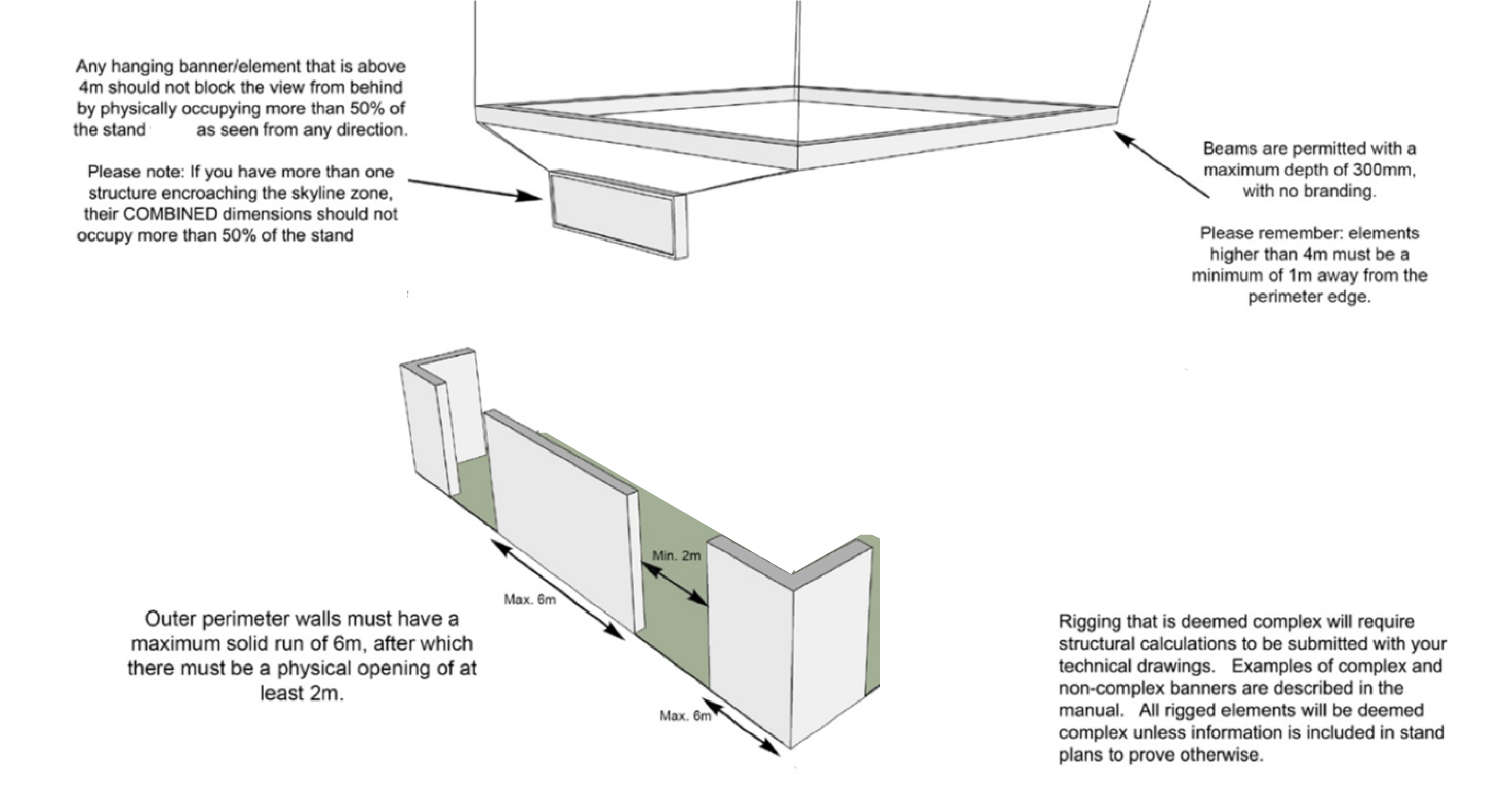

- Internal walls and structures - up to 7m. Please note: 50% of stand space width rule applies to any structures above 4m in height - see Skyline Zone section.

- Hanging banners - maximum rig height of 7m from floor level (i.e. top of the banner / truss at 7m). Please note: 50% of stand width rule applies to any banners above 4m in height - see Skyline Zone section.

IBC must be notified if it is expected that any part of your stand structure (excluding rigged hanging banners) will be higher than 4m, so it can be taken into account during the allocation of space. If you plan to build above 4m, the tall area of the stand (anything above 4m and up to 7m) will be classed as being in the Skyline Zone. When reviewing stand plans Abraxys will only approve tall structures where the view of other stands is not unduly affected.

CEILING DRESSING - HALL 1 STANDS

The tops of all stands in Hall 1 are clearly visible to all guests visiting the Balcony Suites located on the mezzanine level of the hall and are also clearly visible from the upper decks of double decker stands. It is the therefore a show requirement that the tops of all stands in Hall 1 to be finished off in a neat and tidy manner, hiding all unsightly cabling, wiring and raw woodwork using a suitable and permissible material such as flame-retardant muslin. For more information, see Permissible Stand Building Materials.

COMPLEX RIGGED STRUCTURES - IMPORTANT DEADLINE

Stands deemed complex will be asked to submit your structural calculations report produced by your own engineer to Abraxys no later than 5 August. Stand plan revisions or structural calculations not submitted to Abraxys before 20 August will mean that complex elements will need to be removed from stand plan designs.

A Complex Fee to cover the structural engineers fees will apply. The Complex Fee is applicable to all complex rigged structures and includes pre-site checks of your drawing and calculations submitted and onsite sign-off during the construction by an independent structural engineer. The Complex Fee is only applicable to those stands where rigged structures are deemed complex and is to be paid in addition to the Stand Plan Inspection fee.

Once your stand plans have been received by Abraxys, if your rigged banner construction is identified as a bespoke design and build (timber or metal) then this will be deemed complex and you will be required to submit your own engineers written structural calculations report. Your engineers calculations and drawings must include hanging point detailed drawings showing how the frame is hung and the fixings used to secure it. Please include all construction materials and weights. Please note all fixings should be structurally rated.

Non-complex rigged constructions are those that are lightweight aluminium frameworks, usually seen with a fabric/vinyl banner. This would be a proprietary shop bought pre-manufactured and pre-tested lightweight modular banner where no adjustments or additional fixings have been added

Banners will be checked onsite to ensure the construction matches the material and weight information stated on the plan drawing. If any complex structure is modified after the submission of the below information, plans must be resubmitted with details of all modifications.

The following information must be submitted for a Complex Rigged Structure to Abraxys with your Stand Plan Submission:

- Detailed, scaled structural drawings

- Structural calculations

- Specifications of materials used, description of all fixings. Rigging connected to truss must show fixings through entire truss, not just around bottom chords.

- Weight per suspension point and total weight of banner construction

- Risk Assessment

The Complex Fee of GBP 290 (+20% VAT) is applicable to all complex rigged structures and includes pre-site checks of your drawing and calculations submitted and onsite sign-off during the construction by an independent structural engineer. The Complex Fee is only applicable to those stands where rigged structures are deemed complex and is to be paid in addition to the Stand Plan Inspection fee. Payment of the Complex Fee can be made via the secure Abraxys retail site.

- Complex Fee (GBP): https://www.abraxys.online/online-store/IBC-2024-Complex-Fee-p530096687

- Complex Fee (Euro): https://www.abraxyseuro.online/online-store/IBC-2024-Complex-Structure-Fee-p530124524

Abraxys Ltd

Tel: +44 (0) 20 8747 2045

Email: ibc@abraxys.com - No stand plans/forms to be submitted via email. All submission to be made via Stand Plan Submission link.

CONSTRUCTION GUIDELINES

There are a number of strict health and safety guidelines governing the Double Decker design and construction process. For guidance on the main elements of safe construction, please see Double Decker Construction Guidelines. Any construction activity not following correct procedures and deemed unsafe will be stopped.

STABILITY

- Stability at all stages of construction and dismantling

- Identifying the point at which the structure can support itself

- Identifying the permanent elements that ensure stability

- The sequence of construction and the sequence for the removal of any temporary parts

- Calculations indicating the relevant forces and load capability of the structure

- The floor loading capacity of the venue

CONSTRUCTION AND DISMANTLING

- Drawings must clearly identify the sequence of construction, e.g. construction of frame; insertion of legs; fixing of bracing

- A clear plan for dismantling the stand must be identified

- The time available for construction and dismantling of the stand must be taken into consideration

- A safe system of work must be identified within the methods for construction and dismantling, i.e. work equipment; temporary handrails; fall-arrest system

ASSESSMENT OF LOADS

- A realistic assessment of the loads and forces at each stage should be made in consideration of the erection sequence

CONNECTIONS

- The design should consider the safest means of connecting components and, where appropriate, indicate the necessary provision of access equipment and the safe system of work

- Connections shall be simple and effective to reduce the time spent working at height

MATERIALS HANDLING

- The design should take account of the safe handling, lifting, storage, stacking and transportation of the components relevant to their size, shape and weight

CONSTRUCTION METHODOLOGY

The preparation of a construction Method Statement is a vital step in the planning of a safe system of work. The Method Statement must detail the steps taken to build and dismantle the stand i.e. the sequence of construction and the sequence of the removal/breakdown of the stand, identifying the critical controls and procedures to avoid accidents. A safe system of work must be identified within the methods for construction and dismantling of the stand.

The Method Statement for a double decker stand should include:

- Construction sequences i.e. the build and the dismantling of the stand, noting the starting point. Clear identification of the sequence of construction e.g. construction of frame; insertion of legs; fixing of bracing. The time available for construction and dismantling of the stand must be taken into consideration.

- Methods to ensure stability, including the use of temporary components and systems

- The detailed construction scheme that identifies the lifting, alignment and connection requirements of the stand.

- The preferred system to prevent falls from height, the safe means of access and any special platforms or equipment used e.g. temporary handrails, fall-arrest system etc.

- The provision of suitable personal safety equipment and construction equipment with which to construct the structure safely.

IMPORTANT: Work on site will be checked against this information and will be stopped where it does not comply; dangerous work practices will not be tolerated and persons may be removed from the venue if necessary. As much of the construction as is possible should be completed at floor level, then lifted into position. This should include decking and the erection of handrails to ensure a safe place of work on the upper level once lifted, to avoid the need to provide additional safety measures such as temporary edge protection and fall restraint or arrest systems. Please note that 'live' or 'open edge' working at height is strictly prohibited.

Please familiarise yourself with the relevant Dutch Building Standards for Double Decker Stands such as strength, stability and point loads including railings and stairs. It is highly recommended that exhibitors and/or their contractors contact the RAI Licenses Desk for further details before designing their Double Decker stand.

GUIDANCE ON ERECTION AND DISMANTLING OF STRUCTURES

- Method Statement and Risk Assessment of the stand build must be provided and must be followed. All persons involved with the work must be competent to undertake the work and have read and understand the method statement and risk assessments and erection sequence(s).

- Competent supervision is required, and supervisors must be trained and understand the work they are to supervise. They must be able to read and understand the drawings and method statements and ensure that they are appropriate for the structure and its location. Where the methods are changed, the designer shall authorise the change, in writing, prior to the documentation being changed and these must be re-submitted to the Organiser and Amsterdam RAI structural engineer for approval.

- Weights of components should be clearly marked and where necessary, lifting points indicated. Components should be stacked and delivered so that they can be removed in the desired order.

- Deliveries must consider the Floor Loading in the area of erection or unloading.

- Hard hats, safety shoes and hi-vis vests (PPE) are essential for working with steel structures. It may be necessary to cordon off the area of the build when overhead working is taking place.

- Welding and cutting (fabricating) is not allowed within the RAI Amsterdam without the prior written consent of the venue. Please refer to Fire Regulations for Hot Works and Naked Flames.

- Plant and equipment must only be operated by a competent person and copies of their licences or certificates must be available for inspection at any time.

- Lifting the main deck using several forklift trucks is acceptable provided a Method Statement has been accurately filled out and approved by Abraxys.

Hard hats, safety shoes and hi-vis vests (PPE) are compulsory for anyone in the halls during the build-up and breakdown periods.

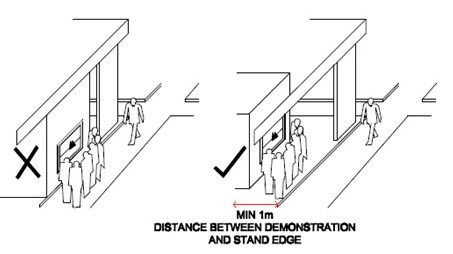

DEMONSTRATIONS & PRESENTATIONS

SPACE ALLOCATION: Adequate space must be provided for the audience within the stand for any demonstrations. All such activity must be conducted a minimum distance of 1m inset from the stand edge. Use of the aisles for the audience is not permitted. The Fire Officer will curtail any activity that creates congestion in the aisles. If wall-mounted monitors on outer stand walls cause obstructions and congestion in the aisles, IBC may request these to be switched off. If you are showcasing 3D effects, you are required to factor in an adequate viewing distance that does not encroach into the aisles or neighbouring stands.

LIVE PERFORMANCES AND USE OF PROPS: If you are performing a timed display of an interactive nature designed to attract an audience by using props, performers or equipment, you are required by law to submit a separate Risk Assessment of that activity. Failure to submit an adequate Risk Assessment for the activity will result in the activity being curtailed.

NOISE LEVELS: Noise levels are a major concern with regards to demonstrations, presentations and performances on a stand. Noise levels should never interfere with or restrict your neighbours from conducting business and as such noise levels will be strictly monitored by IBC. Sound reinforcement is sometimes necessary so that the audience is able to hear what is being said. However, sound levels should never infringe upon neighbouring exhibitors or restrict them from conducting their business while your presentation is taking place.

Whenever loudspeakers are being used, they should be pointed downwards and into the stand - never towards or across the aisles. The sound level at the edge of your stand must be lower than 85 dB (A) for speech and lower than 70 dB (A) for music and sound effects. If after a warning from IBC, if any blatant infringement of the above sound level regulation continues, the sound will be shut down and curtailment of power supply to the stand will be enforced.

To help minimise sound level disputes amongst adjacent stands and potential disruption to neighbours, any exhibitor carrying out timed demonstrations on their stand are asked to inform neighbouring stands in their immediate vicinity prior to going onsite of the time and duration of all planned activity. Proactive dialogue between exhibitors will help to pre-empt and in turn prevent any major timing and sound level clashes between stands.

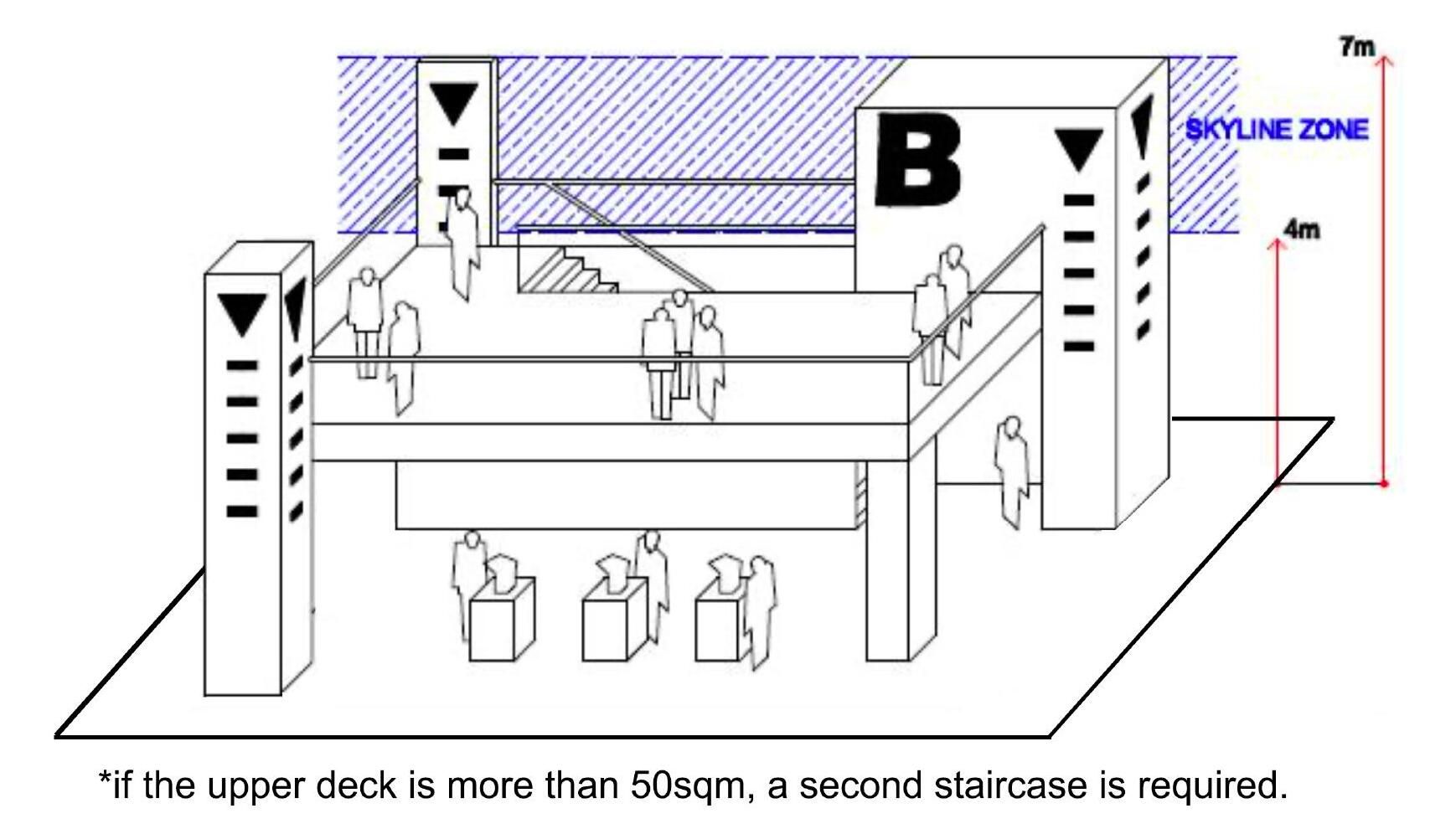

DESIGN RULES

In line with IBC Skyline Zone rule, it is required that the upper deck of any Double Decker stand retain a high element of skyline transparency, constituting an open design, incorporating balustrades and low-level walling. IBC reserve the right to refuse, or request amendments to designs, which in their opinion have a detrimental effect to neighbouring exhibitors or the overall look of the exhibition.

- Double Decker designs that are completely closed in on the upper decks forming high, solid cube or box-like structures will not be permitted.

- Designs should consider the visibility and sightlines of any neighbouring stands and be as open as possible. Consider whether you are building on an island stand, are backing onto other stands or are situated next to a venue wall.

- Double decker stands can be built up to 100% of stand length and up to a maximum of 50% of the stand width but cannot block neighbouring stands with the structure built (both levels).

- If building up to the maximum length/width permitted, Double Decker stands need to consider having walls stepped in, having a greater number of gaps in the lower walling and/or greater upper deck transparency to ensure the sightlines of neighbouring stands.

- Exceptions to this will be considered if any side of the stand is built next to a hall wall.

- Any rigging/signage above the upper deck will also be included into the upper deck area calculation

- The upper deck should be designed to be as open and transparent as possible, especially stand in Hall 1 (see Skyline Rules).

- Where closed-off meeting rooms are required for privacy on the upper deck, approximately 25% of the walling creating the closed off area should retain a degree of transparency and be constructed for example out of see-through materials such as non-tinted glass, see-through muslin etc.

- Ground floor walls, stairways, supporting elements must be as open and transparent as possible whilst retaining structural integrity.

- Air conditioning units may be included but all units must be ordered via the RAI Webshop. These must be included on your initial designs and include how the air is removed from the hall (further details below)

- Smoke/fire detection systems, for any close room/store, must be highlighted on your initial plans.

DOORS ON STANDS

In the interest of health and safety, any doors on a stand must open inwards and have a vision panel. Vision panels must have a clear, see-through, fully transparent element in their design. For example a fully frosted panel with round transparent hole in the middle or, to retain an element of privacy, a vision panel made up of alternate transparent and frosted stripes. If 100% of your vision panel is fully frosted and opaque, it will not be allowed. In some exceptional circumstances it may be deemed safer for a door to open outwards and as such, you will be advised on an individual basis by Abraxys.

IMPORTANT: It is not permitted, under any circumstance, for a door located on a stand edge to open directly into an aisle. These must always open inwards to the store, server or meeting room area and adequate provision in your design needs to be made for this. Any door found opening outwards onto an aisle will be required to be altered on site. If you have any genuine concerns as to whether this can be achieved, please contact Abraxys.

EARLY ACCESS FOR BUILD-UP

Space Only Exhibitors requiring an extra day's build-up are allowed to move into the exhibition halls from 08:00 on Thursday 5 September at a charge of £15+ VAT per square metre of rented space. Early access must be requested via the Early Access for Build-up - Space Only Stands Form (also available in the IBC E-Zone) by 16 August to allow IBC to plan the build-up schedule accordingly. There are significant advantages in applying for early access as unloading is easier and more efficient. For the build of double-decker structures early access is essential. We also highly recommend early access for those exhibitors rigging large lighting trusses.

Please note that all invoices will be sent to the exhibitor directly as IBC hold the contract with the exhibitor. Stand builders can pay the Early Access fee by credit card only - please email finance@ibc.org to obtain a credit card authorisation form. The fee must be paid in full before the Early Access is granted.

ELECTRICS

Electricity for stands can only be installed by the RAI appointed electrical contractor Mansveld Expotech. Please refer to the Health and Safety section for important venue rules and regulations regarding Electrical Safety and ensure your technical installation crew pay particular attention to the power installation and distribution.

Daytime Power operates from 08:00 until 20:00 during the open days of the exhibition and is the principal supply for all equipment and lighting on stands. Continuous Power operates for 24 hours and is intended for use with refrigerators, security equipment, computers etc. Continuous Power must not be used for any form of stand lighting therefore when purchasing Continuous Power, you must also purchase a Daytime Power connection. Service points for all technical connections are situated in the floor of the exhibition halls - floorplans showing their location can be sent to Space Only exhibitors on request. Please note that RAI is equipped with 230V power supplies. If you require 115V, please contact RAI Exhibitor Services so they can assist you with a suitable converter.

Electricity supply for your stand can be ordered via the RAI Webshop. If working on equipment outside of exhibition hours, an electricity supply is mandatory. Exhibitors are advised to discuss their requirements in advance with RAI Exhibitor Services to ensure that their installation meets the needs for such operations.

Attention to details such as power cable diameter, power cable tidiness, proper earthing/fusing and addition of filtering to ensure harmonics (e.g. from lighting dimmers) are not returned to power source. In addition, special attention to earthing is required where a transformer is used to deliver a 110V feed. Mansveld Expotech recommend that the diameter of the neutral conductor within a three-phase distribution has the same thickness as the combined three live conductors.

Exhibitors may be required to install a raised floor to accommodate cabling, so this should be taken into consideration when designing the stand. Electrical connections must not be made under raised floors.

INTER-STAND CABLING

For the routing of video or other cables into the exhibition halls, the Inter-Stand Cabling Form should be completed and submitted to Mansveld Expotech by 24 July (orders after this date will incur a 25% surcharge). Exhibitors who wish to supply own cables, should indicate this on the form (cables must arrive no later than 11 August). Based on requirements, Mansveld Expotech will quote for the work involved.

Mansveld Expotech

Fred van der Kroon

Tel: +31 (0) 20 312 8080

Email: sales@mx.nl

LIGHTING EFFECTS & AV

During IBC, all exhibition halls are completely blacked out so that sunlight cannot interfere with monitor displays. During IBC, all exhibition halls are completely blacked out so that sunlight cannot interfere with monitor displays. From Friday 13 September all hall lighting will be turned off so that the only lighting will be that of the stands, monitors and equipment. During build-up the hall lighting will be turned off from 15:00 to 15:30 on Wednesday 11 September and from 15:00 to 15:30 on Thursday 12 September so that light levels on exhibitors' stands can be adjusted.

AUDIO/VISUAL TECHNOLOGY: IBC prides itself in providing a blacked-out environment for promoting and showcasing the latest broadcast technology. Many exhibitors showcase products that are judged by the quality of the picture displayed on presentation monitors, via projection or on large displays which is one of the many reasons that the IBC exhibition is held in blacked-out halls. As technology advances and new products come to market, the need to balance creative stand design, content display, ambient glare and minimise interference to attendees and other exhibitors becomes ever more necessary. Below guidelines will help to limit the amount of unwanted interference and arbitrary glare from overhead lighting, large format presentation displays, electronic signage and integrated architectural fixtures.

AUTOMATED AND MOVING LIGHTS: IBC prohibits the use of all moving, automated or roving lights or moving gobos as these are deemed distracting and cause unwanted reflections within the halls and from exhibits and overhead rigging.

STATIC AND ARCHITECTURAL: Static or architectural lighting for the enhancement of structural design and the highlighting of equipment or demonstrations is encouraged by IBC, but care should be taken to reduce interference with neighbouring exhibits. Lighting overspill, bleed or lighting instruments focused outside of your stand area are strictly prohibited. Use of static gobos is permitted only within the stand area whilst gobo lighting in exhibition aisles is strictly prohibited. The use of high-resolution rigid LED strips, or high-density flexible LED curtains used for architectural lighting, including their use in subtle colour changing, or for the presentation of audio-visual content including the display of animated or static logos are subject to approval by IBC. Strong neon and flood lighting can be disruptive to adjacent stands and displays, so approval will be required from IBC. Intrusive effects including strobe and fast colour change effects are prohibited. If in doubt, please email support@ibc.org to discuss the matter.

IMPORTANT: The use of very low-density LED screens and LED light curtains for audio visual presentation purposes is prohibited on the basis of general interference - see ‘Low density signage and integrated displays’ section below. To reduce our environmental impact and decrease latent heat, IBC strongly recommend the use of LED/cold lighting technology to allow the air-conditioning system to concentrate on removing the heat generated by technical equipment.

LARGE PROJECTION AND VIDEO DISPLAYS: The use of sophisticated projection technology including but not limited to high density LED displays with a pixel pitch of less than 10mm, video walls or projection and the presentation of high-resolution full motion content is encouraged by IBC. For definition of pixel pitch see fig 1 and fig 2 below. For large video displays care must be taken to minimise heat production, eliminate bleed to neighbouring stands and ensure that line of sight guidelines are adhered to. Due to the nature of large format high resolution LED displays and their high light output, IBC encourage exhibitors to respect neighbouring exhibitors and minimise disruption to walkways and aisles. Care must also be taken in content production as IBC discourage the use of strobe, light chaser and high contrast single-colour effects within LED walls due to its intrusive nature with high light output devices.

LOW DENSITY SIGNAGE AND DISPLAYS: The use of electrical signage such as single, bi-line or text only LED displays, low density LED screens / bars or LED light curtains with a pixel pitch of greater than 40mm for presentation purposes, messaging and logo displays is prohibited by IBC due to health and safety concerns and visual interference for attendees and neighbouring stands. For definition of pixel pitch see Fig 1 and Fig 2 - 'pixel pitch' is the distance between a red (or green or blue) dot and the closest red (or green or blue) dot on a colour monitor. ALL EFFECTS ARE SUBJECT TO AN ONSITE INSPECTION AND APPROVAL AND IBC DECISION WILL BE FINAL.

![]()

PLATFORMS / STAGES

If you intend to install a complex stand, we strongly recommend that you lay a raised floor / platform to hide pipe work and cables. This also gives you greater flexibility to where services are pulled through. Those ordering plumbing services must ensure that pipe work does not run through neighbouring stands without their prior consent.

IMPORTANT: The maximum height for any raised floor is 100mm. Any individual raised areas on a stand higher than 100mm will need to have additional step(s) and possibly a balustrade. All platforms intended for visitor access require provisions for disabled access. Please factor in the height of the platform when designing your stand as the combined height of the platform and separation wall must not exceed 4m. When designing raised platforms, minimising tripping hazards is essential and applying a visible warning if a tripping hazard should exist is key.

If you intend to build a partially raised viewing platform/stage of 600mm or higher with visitor access as part of your stand design, you are required to submit plans with structural calculations for loading and stability to the RAI Licences Desk via the Grandstand Build Permit Application to be issued with a build permit.

RAISED FLOOR / DISABLED ACCESS

In an exhibition hall, as with any public area, equal access for all should be at the forefront of any design. To enable all visitors to access your stand, consideration should be given to visitors with reduced mobility. The maximum height for a raised floor is 100mm. It is a compulsory requirement for a stand with a raised floor higher than 40mm to have an have an incorporated ramp or sloping edges as part of its stand design to create easy access for wheelchair users. When designing raised platforms, minimising tripping hazards is essential and applying a visible warning if a tripping hazard should exist is key. Open corners of stand floors and platforms should be rounded or angled, if not protected by heavy exhibits, to avoid sharp corners and tripping hazards. In most cases, fitting sloping edges to your stand’s raised flooring will solve the access issue in the neatest way and would always be a good first choice solution. When fitting a ramp into a raised/platform floor, ensure that the ramp is made apparent by means of a contrasting colour carpet. For queries regarding the feasibility of safe and adequate provision for wheelchair access within your stand design, please contact Abraxys.

In the case of Double Decker stands (where wheelchair access to the upper deck is not possible/practicable), it is incumbent on the exhibitor to ensure that any services or information that are available upstairs are also available on the ground level of the stand.

REFUSE COLLECTIONS

BUILD-UP AND BREAKDOWN: Exhibitors and stand contractors are required to dispose of all refuse produced during build-up and breakdown using hired containers. Refuse containers should be ordered in advance via the RAI Webshop. Any rubbish left on an exhibitor's stand after breakdown will be charged to the exhibitor.

The RAI recycle paint waste. Stand builders will receive red garbage bags in which they can dispose empty or semi empty paint cans. The red bags are handed out and picked up free of charge. If there is other garbage in these bags, they will not be collected, and the stand builder will be responsible for the refuse. Cleaning of paint brushes in the toilets is prohibited.

The RAI must be informed of any chemical waste for disposal, and this will be collected from stands by the RAI. The waste should preferably be in the original packaging and labelled with the exhibitor's name and stand number. Please contact the RAI Exhibitor Services for the charges involved.

EXHIBITION OPEN DAYS: Refuse will only be disposed of when it is deposited in the special refuse bags and placed alongside the stand at the close of each day. Refuse bags should be ordered in advance via the RAI Webshop.

DONATION ROOM: Many items can be donated to the RAI Donation Room post event - click here for details.

RIGGING

Mansveld Expotech is the sole official rigging contractor allowed to access the RAI roof structure to install rigging points. Third parties are strictly prohibited access and are not permitted to install any rigging points. Mansveld Expotech can assist you in working out the correct rigging plan and can advise on the truss materials, motorised hoists and any customised services. Rigging can be ordered via the RAI Webshop clearly indicating the stand position, hanging points required, guy ropes/steel wires, measurements and weights of any objects.

CEILING HEIGHTS: Suspension wires for hanging signs and lighting rigs can be installed in most areas of the halls. In case of height limitations, exhibitors will be advised. Please note that there may not be a suspension point directly above your stand area and support trussing may have to be fitted on the ceiling above your stand. Due to the complexity of this process, extra costs may be charged for suspension points in some areas. Quotes for suspension points and rigging are made on individual basis. For more information, please contact Mansveld Expotech.

MANUAL AND ELECTRIC HOISTS: Due to Dutch legislation, the use of access platforms for lifting objects of 50 kg or more is prohibited. Mansveld Expotech can make hoists which are certified according to CE and TUV regulations available provided the order is received at least 3 weeks prior to build-up.

COMPLEX RIGGED STRUCTURES: Stands with complex rigged elements will be required to submit structural calculations to Abraxys. Structural calculations not submitted will mean that complex elements will need to be removed from stand plan design. The Complex Fee is applicable to all complex rigged structures and includes pre-site checks of your drawing and calculations and onsite sign-off during the construction by an independent structural engineer.

SEPARATION WALLS

Space Only exhibitors must construct their own freestanding separation wall(s) between their and adjoining stand(s). These should be minimum 2.5m and maximum 4m high. The maximum height of any separation wall must be measured from the venue floor and must include any raised flooring and/or platform. All walls must be self-supportive - cross bracing to a neighbour's wall is not allowed.

IMPORTANT: Where partition walls are constructed over 2.5m in height, it is the responsibility of the exhibitor constructing the wall to neatly dress the rear of the separation wall down to a height of 2.5m in a neutral colour, in harmony with the design of the adjacent stand as agreed by the neighbouring exhibitor. We ask any exhibitor whose separation wall is higher than 2.5m to notify their neighbour of the height of their wall and obtain agreement from them regarding the design treatment to the back of the wall. Logos and branding are not permitted on the rear face of separation walls when these walls overlook neighbouring stands.

If your separation wall is lower than 2.5m, you must be aware that your neighbour's wall below 2.5m will be unfinished on the reverse and will be visible above your stand. It is therefore your responsibility to contact your neighbour to discuss your respective wall heights and to reach an agreement to ensure all separation walls are finished off in a neat and tidy manner. Contacting your stand neighbours eliminates any potential issues onsite with adjoining wall heights. IBC will be happy to provide contact information of the neighbouring exhibitor(s) upon request. IBC strongly advises to record such agreements between stands in writing.

Where a Double Decker stand adjoins another stand, the maximum permissible height of the separation wall is 5m. Separation walls higher than 5m will not be allowed. You will be required to dress the wall on the reverse in a colour agreed with your neighbour. Your neighbour will have the option of placing their logo on the side of the separation wall that faces their stand

SHIPPING & STORAGE

CEVA Showfreight is the official freight forwarder for IBC2024 and have exclusive responsibility for forwarding and handling of all exhibits into and out of the exhibition halls. This covers delivery and removal arrangements, customs clearance and empty crate storage during the event. CEVA are the only company authorised to use mechanical lifting equipment on the loading terraces and in the halls. For information on the CEVA services, please download the brochure.

Build-Up & Breakdown: Delivery vans are allowed onto the loading areas only when there is adequate space. RAI Traffic attendants in conjunction with CEVA coordinate this.

Courier Deliveries: Courier companies are not allowed to deliver packages directly to stands. All packages must be delivered to CEVA, who will hold them for collection by the exhibitor unless written delivery instructions are provided.

Forklift Trucks: Only forklift trucks, cranes and mechanical equipment operated by CEVA are allowed on the loading terraces and in the halls. Exhibitors and/or their agents are allowed to only move hand-portable goods into and out of the halls

Empty Cases Storage: CEVA are able to remove empty packing cases from exhibition stands during build-up, store them for the duration of the exhibition and return them after the exhibition close. Should any boxes stored with CEVA not be empty and contain items of value, CEVA must be informed in writing at the time of collection. Exhibitors must arrange their own insurance cover for the transit and storage period.

Labour Onsite: IBC do not provide labour for handling/moving/unpacking of goods, etc. CEVA can provide this service.

CEVA Showfreight services ordering deadline is 23 August (orders after this date will incur a 25% surcharge). CEVA Showfreight can be contacted on +44 (0) 149 457 3091. IBC and CEVA Showfreight cannot be held responsible for loss, pilferage or damage whilst goods are left unattended on the stand.

SKYLINE ZONE

The following rule is enforced and monitored by IBC in the interest of retaining an open exhibition environment and fairness for all exhibitors. IBC reserve the right to enforce compliance and if advised amends are not implemented, terminate any violation to this rule.

Any structures above 4m and up to 7m is classed as in the Skyline Zone. This zone must be as transparent as possible, and it is each exhibitor’s responsibility to ensure that structures in this zone do not unduly block the through-view to the hall and neighbouring exhibitor stands by masking or dominating the surrounding skyline. Any portion of a structure (column, internal wall, hanging banner or a structure erected from the floor) that is above 4m, should not block the view from behind by physically occupying more than 50% of the stand width from any direction. For example, if your stand is 10m x 30m, then the approximate dimensions of a box banner occupying the Skyline Zone should be a maximum of 5m in width x 15m in length.

If a truss is higher than 4m, it is not possible to clad / cover the truss. Beams are permitted with a maximum depth of 300mm with no branding. If you have more than one structure encroaching the Skyline Zone, their combined dimensions should not occupy more than 50% of the stand width.

STAIRCASES

The number, location and width of staircases necessary on a Double Decker stand is judged on a case-by-case basis by the RAI Amsterdam Licenses Desk when issuing Double Decker Permits. Consideration is taken of the direction of traffic flow, floor area used by the public excluding private staff areas. As a general rule an upper deck floor area of 50sqm or over will require two or more staircases. IBC and Abraxys are NOT able to advise on the definitive number and or configuration of staircases on a Double Decker stand. RAI Amsterdam Licenses Desk will advise on the layout and number of staircases during the second stage of Double Decker stand plan approval. Should they require that the design be changed on the grounds of health and safety and structural soundness, their decision is final. Any additional costs that may be associated with this will be the responsibility of the exhibitor. Double Decker stands are not fully approved until passed through the second stage of approval by the RAI Amsterdam Licenses Desk. IBC strongly advise designers to contact the RAI directly with regards to guideline advice on such integral elements of a Double Decker stand design as layout and number of staircases and emergency exits before they finalise their design plan ideas.

STAND BOUNDARIES

The stand construction should not go beyond the rented space. Fire points and emergency exits must remain visible and accessible under all circumstances. No part of the stand, exhibit, fixture or fitting including fascias, signs, lighting (including long arm spots), display items ie camera/sound/lighting cranes or booms, corner posts etc, shall project into or overhang the aisle or obscure any fire or exit signs - IBC reserve the right to remove any such item. This rule also applies to the projection of logos onto the floor, which should always be kept within the stand space.

Traditionally, the broadcast industry allows camera cranes and microphone booms to protrude from the stand halfway over the aisle, but not further, and definitely never over a neighbouring or opposite stand. Any protruding arms should be over 2.5m from the venue floor and not interfere with anyone walking underneath. These rules exist to ensure that the various stands are built at IBC to produce a harmonious exhibition environment. Exhibitors are therefore advised to contact neighbouring exhibitors to coordinate aspects such as shared walls and presentation timings.

STAND NUMBERING

Stand numbers consist of the hall number, followed by a full stop (.) and then an aisle letter (capital) and a two-digit number, indicating the location in that hall. Any letter and two-digit number can appear in any of the halls, so the hall number should therefore always be included with the stand number, e.g. 3.C29 or 10.A34.

Shell Scheme Stands: RAI Exhibitor Services arrange the display of the stand number on all Shell Scheme stands. No floor sticker is provided.

Space Only Stands: Up to two stand number labels will be provided for every Space Only stand.

SUSTAINABILITY

IBC is committed to promoting sustainable practices and recommend the use of reusable structures which will reduce the amount of waste produced at the event. When planning your stand design, please review the sustainability practices of your appointed stand builder/contractor. As an exhibitor your aim to reduce the use of disposable stand materials and replace them with an environmentally friendly alternative using materials that can be reused at future events. For further RAI CSR initiatives, please click here.

When planning your attendance at IBC, please consider the following:

- Stand design – What the elements are made from? Are they made from sustainable materials? Can they be recycled? Are they being removed from the show and responsibly processed?

- Stand re-use – Is your stand being used at multiple events? Can your stand structure be used again? Are you renting or do you own the stand outright? How much is single use and how much is recycled/re-used?

- Graphics – What are your graphics printed onto? Are the fabrics/panels re-useable/recyclable? Are the inks used sustainably sourced?

- Single-use items – What % of your stand is single use? If using carpet/flooring, is this being re-used or donated post show? Can you reduce the single use items for the show?

- Stand builder supply chain – Can your stand builders evidence their sustainability? Do they provide data on how sustainable your stand is? How far does the stand have to travel to get to the RAI? Is the labour used to build your stand local to the RAI? How far have they travelled?

- Catering – How sustainable is the catering your hiring? Are the cups/plates/cutlery re-used or single use? Are you giving away single use water bottles or refillable water bottles?

- Literature / giveaways – We encourage stands not to distribute literature and single use give-aways. Are you using QR codes to share information? Are you using a prize-giveaway to promote your stand?

- Travel – Is your travel sustainable? Are you counting the carbon miles for each person? What sustainability initiatives does your hotel promote?

TRANSMITTERS / LICENSING

The highly concentrated use of radio frequency will need to be carefully planned and organised so that all the users can share the spectrum safely without causing interference. It is illegal to use transmitters except under a licence issued by the Netherlands Radiocommunications Agency or where there is a specific exemption from licensing, proved that it fulfils the requirements of the R&TTE Directive. Typical examples of equipment for which a licence is required: radio microphones, wireless TV cameras, PMR equipment, microwave links, satellite equipment, radio and TV transmitters, and remote-control equipment.

Around the RAI vital frequencies are used by emergency services and civil aviation. Use of these frequencies without a licence obtained by exhibitors will not be tolerated and may lead to a fine or confiscation of the equipment. The licence application can be found on the Netherlands Radiocommunications Agency website. The application should be submitted to the Radiocommunications Agency at least two weeks in advance of IBC.

Netherlands Radio Communications Agency

Tel: +31 (0) 88-0416000

Email: info@rdi.nl

VEHICLES ON STANDS

RAI Amsterdam has strict rules governing the display of vehicles within the exhibition halls. Engine driven vehicles, vessels or machinery will only be permitted to be displayed during the exhibition if specifically agreed with IBC prior to the show. Before being admitted, fuel tanks and pipelines must be emptied and closed with the fuel caps locked and any batteries must be disconnected. This does not apply to vehicles, etc. using diesel oil or other fuel with a combustion point above 55ºC. Battery clamps must be loosened. In case of vehicles in which 230 V interior lighting has been fitted, a plug connection must be used so that in the event of an emergency the current can be quickly disconnected. Diesel engine emissions contain carcinogenic substances (including soot), and the RAI are obliged by law to control exposure to these within the convention centre. Any vehicles on stands must be declared via the Health & Safety approval process.

Electric Vehicles on Stands

The following details were added in 2023 to allow electric vehicles to be displayed on stands:

-

Vehicles can drive or be towed into the halls.

-

Once in position they must disconnect the battery.

-

The ignition key must be at least 5 meters away.

-

The car must not be switched on at any point whilst in its final position.

-

The car must not be charged within the halls, they cannot be connected to a charger at any point to ensure that there is no electricity running outside of the battery.

-

All vehicles must be signed off by RAI Safety.

-

This applies to all electric vehicles. Cars, boats, steps, etc.

Should you want to position a vehicle on your stand, please ensure this is verified by Abraxys as part of your stand approval. Abraxys will advise on the delivery and removal times and processes. Please include your exhibiting company name, stand number and information about the vehicle you want to place on your stand (type of vehicle, dimensions, weight etc.).

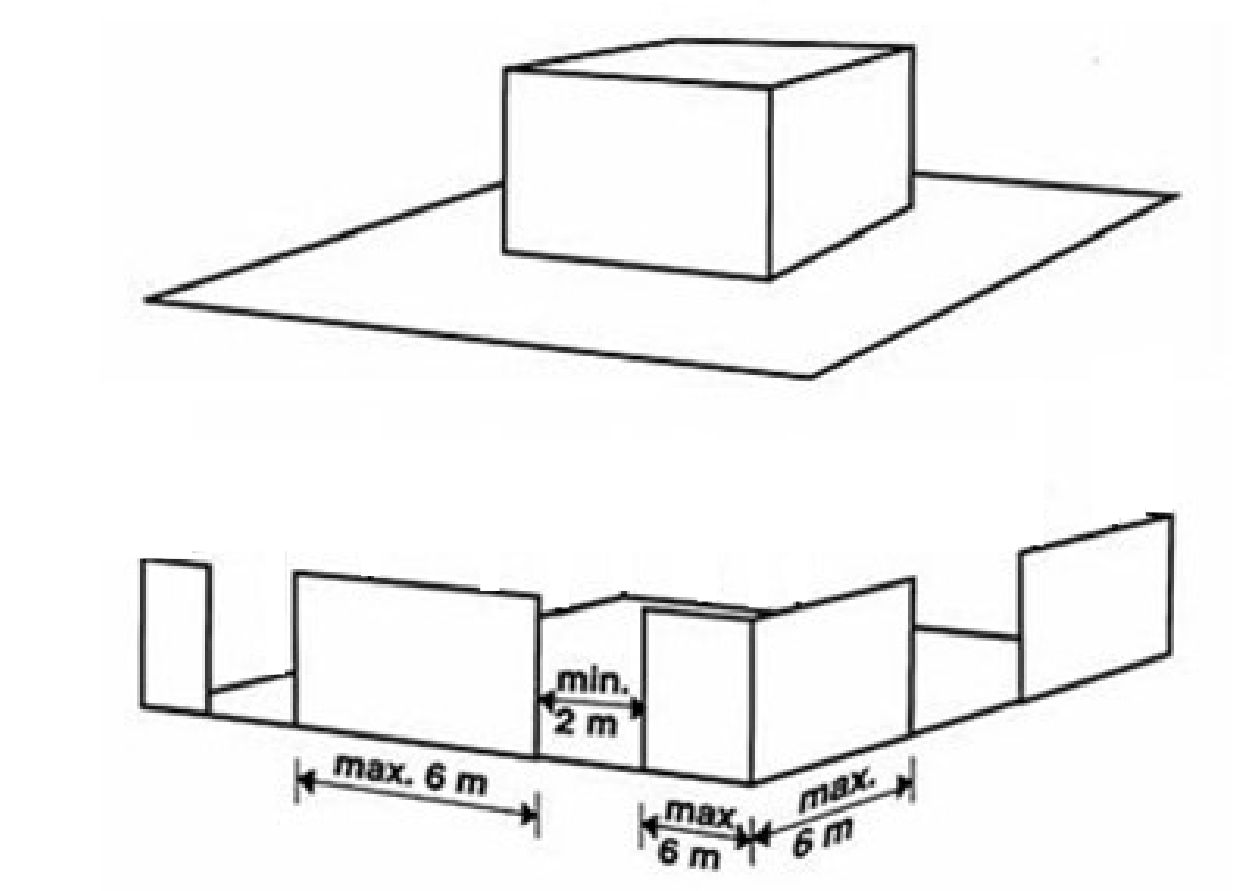

WALL LENGTH

For health and safety, solid runs of stand walls exceeding 6m in length along gangway edges are forbidden - walls need to have natural physical breaks of 2m wide gap every 6m. Walls should be stepped in 1m if above 4m and maintain an open design. The use of glazing panels instead of a physical break in the walling will not be allowed as they constitute a physical barrier. It is generally accepted that an inviting environment is created by an 'open architecture' with minimal outside walling and a structure built in the middle of the stand. This is to avoid interfering with the overall view of the halls, mask or block neighbouring stands or hinder visitor traffic on the stand. Designs should ensure that neighbouring stands will not be blocked from view by long runs of walls. IBC reserve the right to curtail any violation to this rule.

WATER & WASTE

To order a water connection and waste-pipe facilities for your stand, please visit the RAI Webshop. Water and waste connections CANNOT be ordered for stands in Hall 14.

There are strict rules and regulations governing the use of ‘open’ and flowing water for stand displays. The presence of sprayed and/or atomised water is strictly prohibited.

For any water features on stands, you will need to obtain an official Water Object Permit from the RAI by 15 August. RAI Licencing Department will assess whether additional safety measures are needed, such as a Legionella filter. For installing and using a Legionella filter, you will receive a separate quotation from the RAI Exhibitor Services. Any water feature or display must be included on your stand design plan and your Risk Assessment.